- MW5 Series Lifting Electromagnet Billet shear, also called billet shearing machine, is applied to cut steel billet (800℃) on the continuous casting line. Compared with flame cutting, it can reduce the processing cost. Using hydraulic drive, it has stable operation, no vibration, safe and reliable ...

- MW61 Series Lifting ElectromagnetLifting electromagnet or lifting magnet is used for lifting iron, steel scraps, bars, coils, etc. It can be used in steel plants, ports and other industrial sites. It’s characterized by large attracting force, deep magnetic penetration and long life. A lifting magnet can be used for moving scrap steel from...

Lifting Magnet

Description:

This lifting magnet can lift and transport magnet-conductive materials like steels. So this device can be applied to metallurgy, mine, Lantekyhinery industry, communication industry, etc. In addition, this lifting electromagnet can be used as electromagnetic manipulator to hold magnet-conductive materials.

Features:

1. Due to the adoption of totally sealing structure, this lifting magnet has well moisture-proofing performance.

2. Lifting magnets are designed by computer, so they feature reasonable structure, light weight, strong attraction force, low energy consumption, etc.

3. The electrical property and mechanical property of the energizing coils are improved greatly after processing by special technology. The heat-resistant performance of insulating material can reach C Grade; the service life of lifting magnet is long.

4. Compared with the general lifting electromagnets, the rated power-on sustaining rate of these products in our company can be improved by 50%-60%. Therefore, the efficiency of lifting magnet is also improved.

5. For the adoption of unique heat-protection method, the temperature of the attached materials is increased from 600℃ to 700℃. So the application range of the high temperature type lifting electromagnet is expanded greatly.

6. Lastly, the installation, operation and maintenance of such lifting magnet are all simple and convenient.

Attention for Choosing:

1. The normal temperature type lifting magnet is suitable when the temperature of the attached material is below 100℃. When the temperature is over 100℃, please choose higher temperature type.

2. The power-on sustaining rate is above 60%, high frequency type lifting magnets are more suitable.

3. The depth of diving should be less than 100m. Its parameters are the same with that of normal temperature type lifting electromagnets. Please do not hesitate to contact us if you need these diving type products.

4. The using temperature of normal temperature type lifting magnet should be -20℃~80℃. And the high temperature type should be -20℃~80℃. The altitude should be less than 2,500m.

5. 1). The commutation control equipment and its accessories should be added according to consumed power when using single unit;

2). When several lifting magnets are used together, you should choose equipment and accessories according to the sum of the consumed power (current).

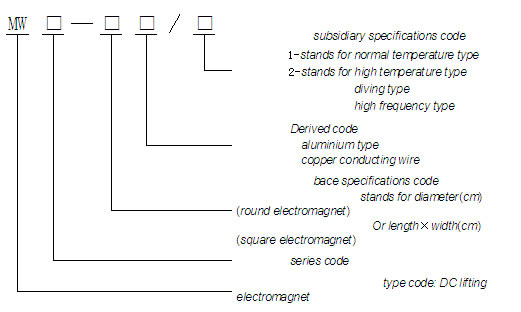

Model Designation:

Main Technical Data:

1. Normal temperature type lifting magnets (used under normal temperature, power-on sustaining rate TD-60%, DC-220V)

| Model Attention | MW5- 70L/1 | MW5- 110L/1 | MW5- 130L/1 | MW5- 150L/1 | MW5- 165L/1 | MW5- 180L/1 | MW5- 210L/1 | MW5- 240L/1 | ||

| Dimension | A | 700 | 1100 | 1300 | 1500 | 1650 | 1800 | 2100 | 2400 | |

| B | 800 | 1080 | 1210 | 1220 | 1230 | 1470 | 1800 | 2020 | ||

| Mass (㎏) | 500 | 1250 | 2050 | 2700 | 3400 | 4100 | 6800 | 9000 | ||

| Power(kw) | 3.2 | 7 | 11.9 | 15.6 | 19.8 | 22.4 | 27.9 | 33.9 | ||

| Cold-state current(A) | 14.7 | 35.1 | 54 | 71 | 90 | 102.4 | 127 | 154 | ||

| Lifting capacity(kg) | Steel ball | 2500 | 6500 | 8500 | 11000 | 13000 | 14500 | 17000 | 26000 | |

| Steel ingot | 380/200 | 1000/800 | 1400/1100 | 1900/1500 | 2300/1800 | 2750/2100 | 3200/2500 | 4800/3800 | ||

| Steel scrap | 120/100 | 450/400 | 700/600 | 1100/900 | 1350/1040 | 1600/1350 | 2000/1600 | 2850/2250 | ||

Note: The technical data of lifting electromagnet used for diving is same as that of the normal temperature type electromagnet.

2. High frequency type lifting magnets (used under normal temperature, power-on sustaining rate TD-75%, DC-220V)

| Model Attention | MW5- 110L/1-75 | MW5- 130L/1-75 | MW5- 150L/1-75 | MW5- 165L/1-75 | MW5- 180L/1-75 | MW5- 210L/1-75 | MW5- 240L/1-75 | ||

| Dimension | A | 1100 | 1300 | 1500 | 1650 | 1800 | 2100 | 2400 | |

| B | 1270 | 1290 | 1360 | 1670 | 1600 | 1900 | 2020 | ||

| Mass(㎏) | 1500 | 2280 | 3180 | 3840 | 4690 | 7500 | 9800 | ||

| Power(kw) | 6.1 | 9 | 11.3 | 12.2 | 16.3 | 21.7 | 25.9 | ||

| Cold-state current(A) | 27.7 | 40.9 | 51.4 | 55.5 | 74.1 | 98.6 | 117.7 | ||

| Lifting capacity(㎏) | Steel ball | 6500 | 8500 | 11000 | 12500 | 14500 | 21000 | 26000 | |

| Steel ingot | 1000/800 | 1400/1100 | 1900/1500 | 2300/1800 | 2750/2100 | 3500/2800 | 4800/3800 | ||

| Steel scrap | 450/400 | 700/600 | 1100/900 | 1300/1100 | 1600/1350 | 2200/1850 | 2850/2250 | ||

3. High temperature type lifting magnets (used under high temperature<below 700℃>, power-on sustaining rate TD-75%, DC-220V)

| ModelAttention | MW5- 70L/2 | MW5- 110L/2 | MW5- 130L/2 | MW5- 150L/2 | MW5- 165L/2 | MW5- 180L/2 | MW5- 210L/2 | MW5- 240L/2 | ||

| Dimension | A | 700 | 1100 | 1300 | 1500 | 16500 | 1800 | 2100 | 2400 | |

| B | 824 | 1225 | 1280 | 1330 | 1350 | 1515 | 1912 | 2100 | ||

| Mass(㎏) | 520 | 1690 | 2300 | 3260 | 3800 | 4700 | 7550 | 9800 | ||

| Power(kw) | 2.81 | 5.28 | 8.9 | 11.3 | 14.3 | 16.7 | 22 | 25.9 | ||

| Cold-state current(A) | 12.77 | 24 | 40.5 | 51.4 | 65 | 75.8 | 100 | 117.7 | ||

| Lifting capacity(㎏) | Steel ball | 2500 | 6500 | 8500 | 11000 | 1300 | 14500 | 17000 | 26000 | |

| Steel ingot | 380/200 | 1000/800 | 1400/1100 | 1900/1500 | 2300/1500 | 2750/2100 | 3200/2500 | 4800/3800 | ||

| Steel scrap | 120/100 | 450/400 | 700/600 | 11000/900 | 1350/1040 | 1600/1350 | 2000/1600 | 2850/2250 | ||

Note: For normal temperature type and high frequency type lifting electromagnet, the adoption of high field excitation mode can further improve their lifting capacity. For large electromagnet, the adoption of over energizing can accelerate ascending speed of the current, and play a stronger role in lifting capacity.

The products are widely used in the industry of metallurgy, forge and press, casting textile, chemical fiber, and waste recovery and so on. We have owned the self-managerial Import and Export Authority for several years. Our products have been exported to Europe, America, Middle East Africa and the Southeast Asia regions. The diving type lifting electromagnet can be applied when lifting and transporting material in water when installed in these machines.